Thrive in ’25: Cutting Costs & Boosting Efficiency

UK businesses continue to navigate a challenging financial environment in 2025, where persistent high energy prices and increased operational costs demand innovative solutions to maintain profitability. The recent introduction of higher employer contributions, rising wage requirements, and sustained energy costs mean that efficiency has become more essential than ever.

This month, in Series 2 of our newsletter on refrigeration energy technologies, we delve deeper into practical solutions that can deliver immediate and significant savings. At Ultra, we’re committed to helping your business respond proactively to these challenges. By harnessing the latest advancements in intelligent refrigeration automation and energy management systems, your business can reduce energy consumption, lower maintenance expenses, and enhance sustainability. Discover how Ultra’s tailored technologies can help you remain resilient, competitive, and profitable in this evolving economic landscape.

The Ultra Energy-Saving Technology Series

Following on from last month’s exploration of Electronic Expansion Valves (EEVs) in Series 1, we’re continuing our journey into the cutting-edge refrigeration technologies offered by Ultra. In Series 2, we’ll dive deeper into another key innovation: heat recovery systems.

Each of these advanced technologies, from intelligent controls to efficient heat recovery solutions, provides tangible and immediate energy savings. However, their real strength lies in integration—when combined, they deliver maximum efficiency, substantial cost savings, and significant environmental benefits. Stay with us as we continue uncovering the smartest ways to optimise your refrigeration systems, ensuring your business remains profitable and sustainable in ’25 and beyond.

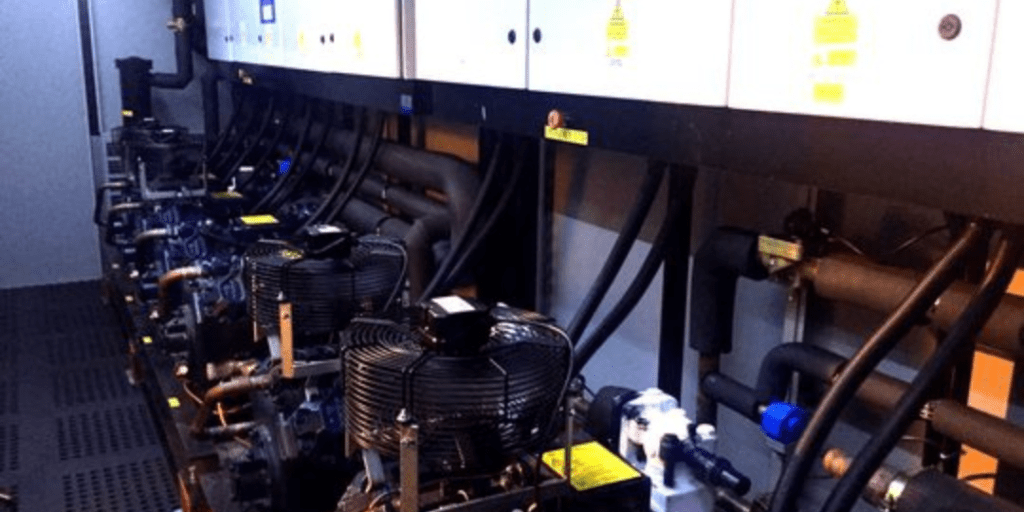

Series 2: EC Condenser Fan Motors

Efficient Fan Control for Enhanced Energy Savings

✔ Lower Power Consumption = Immediate Energy Savings

✔ Variable Speed Operation = Optimised Performance in All Conditions

✔ Reduced Noise and Vibration = Improved System Lifespan and Reliability

Industry Data Supporting These Savings

- A European Commission study highlighted that replacing conventional fan motors with EC motors can achieve up to 30% energy savings due to their high-efficiency operation.

- ASHRAE research confirms EC motors deliver substantial reductions in fan power usage, especially under partial-load conditions.

- A case study by Emerson reported energy reductions of approximately 20-30% when commercial refrigeration systems switched to EC condenser fan motors.

All of these benefits result in quieter operation, extended equipment life, enhanced reliability, and significantly lower energy bills.

Can’t wait for next month’s instalment? Contact us now for a one-on-one meeting with our design engineers to find the optimal energy solutions for your refrigeration.

Spotlight Project

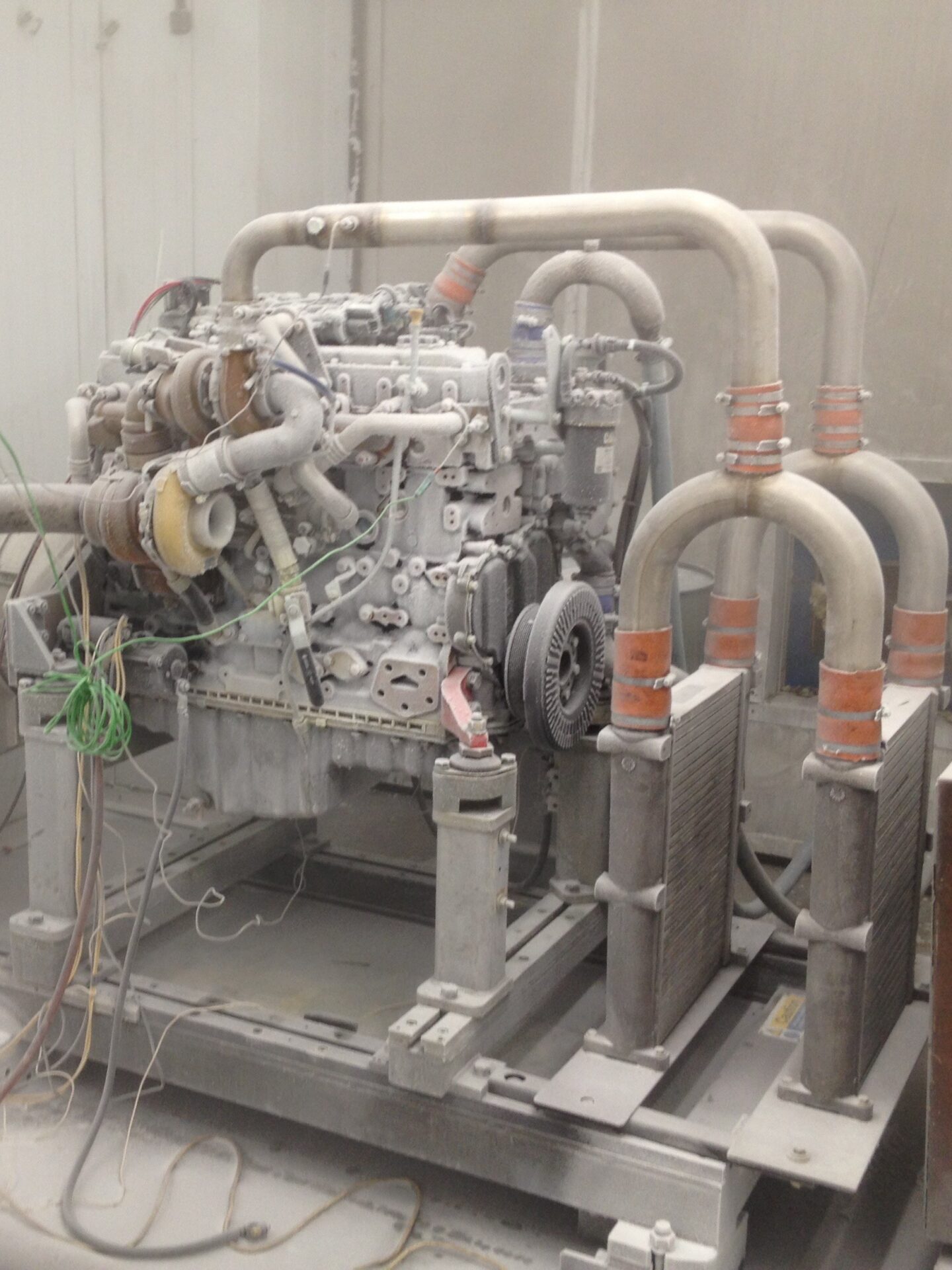

Can Ultra Handle -45°C in a Test Chamber? Absolutely!

When dealing with extreme temperatures, precision, safety, and reliability are everything. That’s exactly what our Service & Maintenance team delivered on a recent project—successfully replacing a large evaporator in a -45°C test chamber.

Test chambers operating at these ultra-low temperatures are critical environments, and any disruption must be managed with expert care. The customer faced the challenge of replacing a core component without compromising the chamber’s integrity or long-term reliability.

Access, Disassembly & Installation – Done Right

Working in these environments requires not only technical expertise but also careful planning. The evaporator swap involved:

❄ Deployment of specialist access equipment to safely reach the installation point

❄ Full disassembly of the air handling unit to extract the aging evaporator

❄ Meticulous installation of the new, high-performance evaporator unit

Cleaning, Conditioning & Commissioning

To ensure a flawless recommission, the team also undertook a full system service:

✔ Replaced system oil and refrigerant

✔ Installed new oil filters and filter driers

✔ Performed a triple evacuation to eliminate all moisture and contaminants from the system

✔ Recommissioned and tested the plant, achieving consistent performance all the way down to -45°C

The Result: A Chamber That’s Colder, Cleaner & More Reliable

By trusting Ultra with this complex task, the client avoided prolonged downtime and ensured their test chamber could continue operating at peak performance.

✅ Improved system efficiency and reliability

✅ Cleaner system internals, reducing risk of future faults

✅ Ready for continuous operation at extreme low temperatures Our Service & Maintenance team has once again proven that no job is too cold—or too complex—for Ultra.

Running Aging equipment doesn’t just risk breakdowns—it costs more to run and maintain. Whether it’s time for a full upgrade, a targeted component replacement, or a smarter service strategy, Ultra’s expert team can help. With a focus on preventative maintenance and energy-efficient solutions, we’ll ensure your refrigeration system is reliable, compliant, and cost-effective. Get in touch to see how we can keep your plant running at its best.