The term ‘AI’, for many, conjures up a scary image of computers taking over the world, whilst for others it is one of the most exciting areas of technological advancement. But what can it do for our refrigerations systems?

Firstly, AI is not new technology, in fact the journey began with the pioneering work of Alan Turing, a British mathematician and logician in 1950.

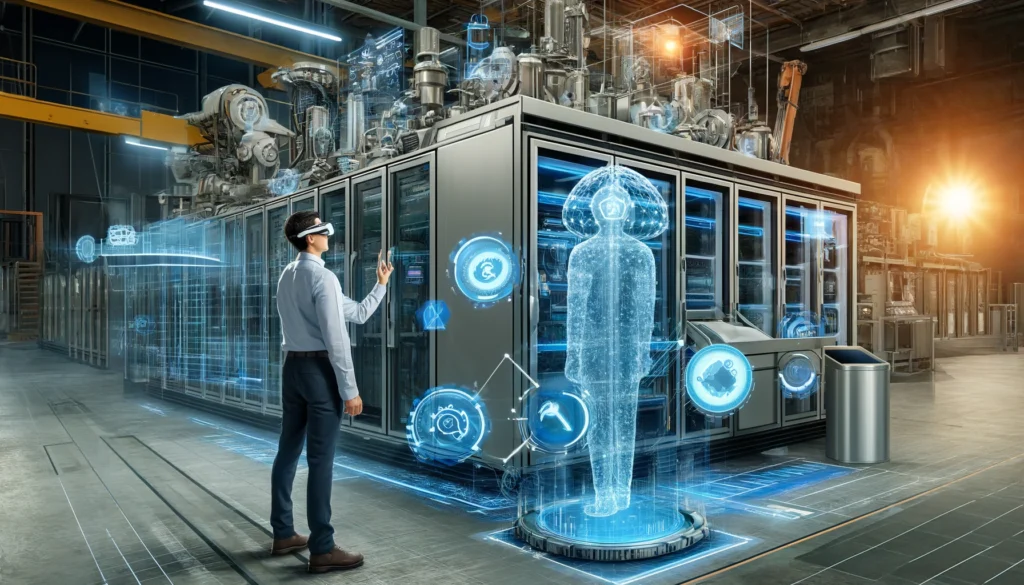

For over a decade, Ultra has been at the forefront of integrating data-driven AI into our control systems. Our cutting-edge technology interprets temperature and pressure data, along with other critical inputs and outputs, to detect potential failures and perform self-diagnoses. This innovative approach not only assists engineers in fault finding but also ensures quicker repairs, allowing our equipment to remain operational even in the presence of minor faults.

Operations Director, Ant Lomas, recalls “I remember sat in front of the computer monitor viewing the various pressure and temperature readings and watching what was happening. After enough time and studying all the information, I was able to determine the root cause of a fault and advise the engineering team. I figured if I could make this diagnosis then why not a computer?”

This approach as enabled us to continuously monitor key parameters such as temperatures and pressures and when an anomaly is detected, the system performs a series of logical tests to identify the root cause of the issue. This self-diagnosis capability significantly reduces the time engineers spend troubleshooting, leading to quicker and more efficient repairs. Additionally, our systems are designed to tolerate minor faults, maintaining functionality and preventing complete shutdowns, which is crucial for industries that rely on uninterrupted refrigeration.

The Power of AI in Refrigeration

Artificial Intelligence (AI) has made significant strides in recent times, and at Ultra we are excited about what the future may hold by harnessing the power of AI to optimise the performance, efficiency and reliability of our refrigeration systems. By analysing real-time data, AI algorithms could predict potential failures before they occur, optimise set-points to suit specific conditions and maximise energy efficiency. In the future, large-language-model AI machines could configure complex and time consuming commissioning set points such as defrost times, lighting schedules, valve and compressor management, and, pressure and temperature settings across large installations just by voice commands.

Looking Ahead

As AI technology continues to advance, Ultra is committed to staying at the cutting edge of innovation. We are constantly exploring new ways to enhance and improve the performance and reliability of our refrigeration systems. The introduction of advanced AI algorithms may be just one more way to provide our clients with the most advanced, reliable, and efficient refrigeration solutions available.

The integration of data-driven AI into our systems has been developed and enhanced over the last 10 years, and by continually monitoring and interpreting critical data our control systems have helped to diagnose potential issues, ensure quicker repairs, enhance equipment reliability and maintain continuous operation. As we continue to innovate and evolve, we remain dedicated to providing our clients with the best possible refrigeration solutions utilising the latest technologies.