Operations Director, Ant Lomas discusses his recent shopping trip!

“If, like me, you find a trip to the local supermarket not a particularly pleasurable experience but your ‘better half’ insists that you go along, it is likely you’ll probably notice them shivering as they enter the chilly aisles by the refrigerated display cases.

On a recent occasion, this was particularly noticeable – it was freezing!

Like any self respecting fridge engineer, whilst she was quickly choosing the goods, I’m wondering why it is so cold – checking the air curtains, monitoring the temperature displays, and feeling the shelf temperatures.

I noticed the produce cases running at a very low temperature (+1ºC) which led me to thinking about the unnecessary energy consumption; cooling product that doesn’t need to be so cold and, of course, the subsequent effort of having to replace that heat back into the store again.

The aisle was certainly cold and I bet that many shoppers pass through quickly due to the ‘cold aisle syndrome’ often missing the retailer’s marketing intentions.

That experience isn’t unusual, our ‘top-up shop’ takes place around once a week at a well known German discount retailer. The first aisle is really cold and uncomfortable and even I, having worked inside freezers and coldstores for years, feel the need to make sure I’ve got my coat with me, even during the summer! Crazy!

I’m sure that much of the energy waste here is down to the case design – clearly many retailers have chosen not to fit glass doors. I’m personally in favour of that – they get in the way of sales, restrict the aisle width when doors swing open, prevent the person shopping in the case next to you when the door slides to the side, and my experience shows they are costly to maintain – often breaking hinges, glass or, where I get particularly irritated, when the return springs don’t work and the doors get left open anyway!

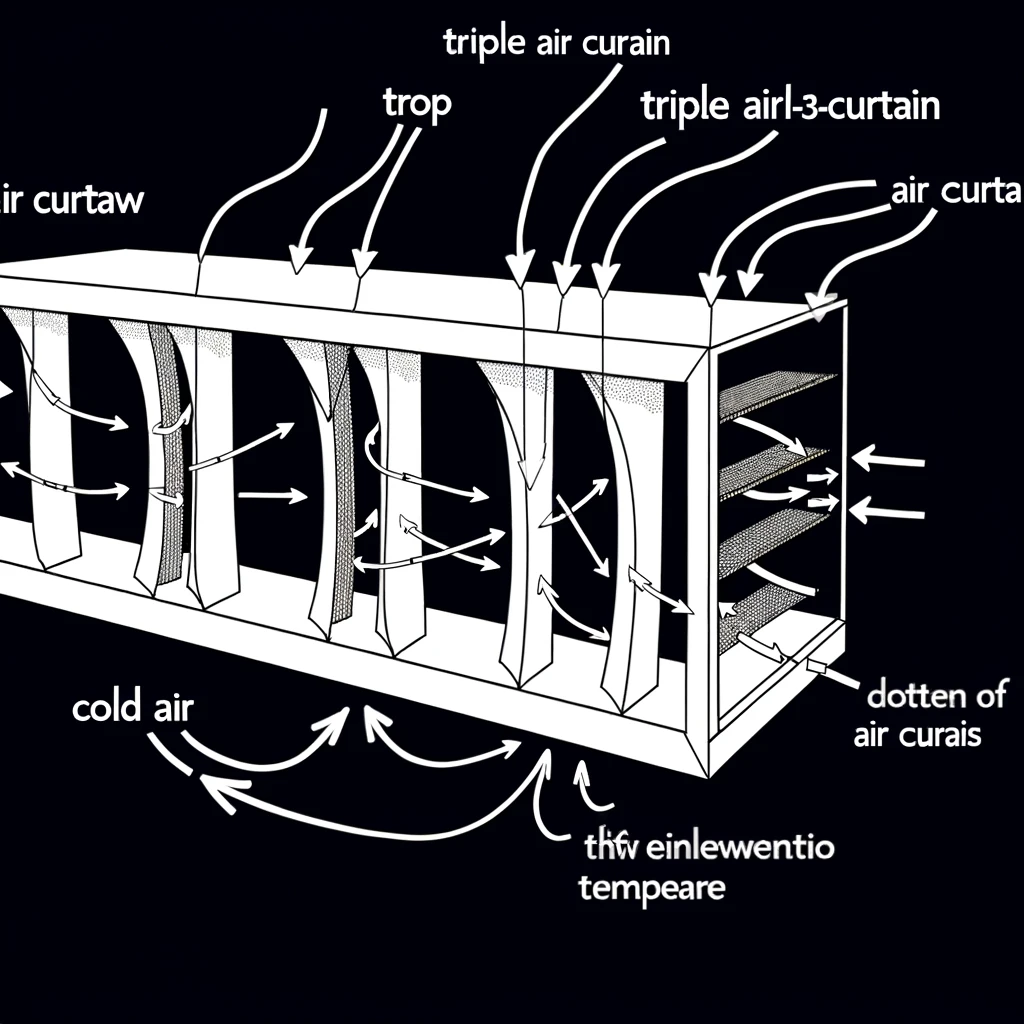

However, if using open-fronted cases, this can all be avoided by good engineering design. A dual or triple air-curtain case may cost more, but the savings in the long run are going to be huge; and I expect customers will spend more time shopping there too if the aisle is more comfortable.

But back to the first point, how many of these fridges are poorly commissioned and are running too cold, or even too warm and leading to food wastage? It can’t just be the 2 retailers within 5 miles of my house!

I’m out to bet that I could find an incorrect setting in any supermarket anywhere – big statement… want to hold me to the challenge?

One of our oldest customers (I mean – not in age, but he has been a customer for a very long time – although he is knocking on a bit now!) contacted me with this very issue…”

Enter Ed Vann, the proactive operator of Budgens Peterborough. Ed was well aware that following years of product changes and re-merchandising initiatives, that things probably weren’t as efficient as they could be.

Recognising the need for efficiency, Ed embarked on a journey to optimise his refrigeration equipment. By asking Ultra to recalibrate set points and make targeted adjustments, we achieved a remarkable 7% reduction in his energy consumption.

In a sector where energy expenditure can be substantial, even marginal gains can lead to substantial savings and a reduced carbon footprint. Ed’s endeavour serves as a beacon of inspiration for fellow operators and underscores the transformative power of conscientious energy management practices.

But what exactly does recommissioning set points entail, and how can it drive energy efficiency in commercial refrigeration?

“At its core, recommissioning involves fine-tuning the operating parameters of refrigeration systems to optimise performance while minimising energy usage. This process typically involves adjusting temperature and pressure settings to suit the product being stored, optimising defrost cycles, and ensuring that equipment operates within optimal parameters.” – Ant explains.

“For Ed Vann, this proactive approach translated into tangible benefits for his business. By recalibrating set points and implementing targeted adjustments, he was able to achieve substantial energy savings without compromising on the integrity or functionality of his refrigeration systems.”

The success of Ed’s initiative underscores the untapped potential that exists within the realm of commercial refrigeration.

Moreover, Ed Vann’s experience serves as a compelling case study for the broader industry, highlighting the practical feasibility and tangible benefits of implementing energy-saving measures without the need for costly upgrades or renewals.

As we look towards the future, it is imperative that we continue to champion sustainability and embrace transformative practices that drive energy efficiency, especially if there are commercial savings to be made along the way. No matter how small the result, these simple gains have a positive impact.

“A quick web search reveals there are over 12,000 supermarkets in the UK, there’s a strong possibility that every one of those could be wasting a similar amount of energy”

Like with Ed, Ultra can work with retailers to ensure the best results in temperature, efficiency and practicality. Contact us to find out more.