CASE STUDY

INNOVATION: iAIR WITH IPP

DAVID KNIGHT RETAIL

Our first iAir client, David Knight Retail, needed to reduce his heating bill with the escalating cost of energy. Heating in convenience stores is required for a longer period due to the heat being removed by the refrigerated display cabinets.

Headline Results

- 25% reduction in total kWh used

- Improved air distribution and more comfortable store conditions

PROJECT DETAILS

The existing heating system was a gas to air system comprising a Powermatic gas fired air handling unit. The heated air was distributed to the sales floor via insulated duct work. The air handling unit was able to introduce fresh air. However, it had been necessary to disable this feature due to the dew point of the fresh air being lower than the refrigerated cabinet external surface temperature resulting in condensation.

The store underwent a major refurbishment at the beginning of 2021. As part of the project, the existing suspended ceiling was to be removed to give the store a more “industrial” stripped back ambience. Some additional iAir cabinets were added and a new refrigeration energy efficient refrigeration plant for the LT cabinets and existing chilled and frozen cold stores formed part of the initial brief.

The new refrigeration plant was designed as an IPP to recover all of the waste heat from the two iAir systems. New brazed plate heat exchangers were added to the iAir systems to act us condensers. These loads were viewed as evaporator loads to the new IPP pack. There were some modifications to the control strategies to prevent partial and free air cooling when heating is required. As with all IPP systems, the heat is transferred to a low pressure hot water system. The heat is delivered to the sales floor and warehouse via hydronic fan coils. The hot water system is also connected to the door curtain above the front entrance to the store to further the energy that is consumed.

CLIENT FEEDBACK

The store temperatures are the most comfortable they have ever been for both his customers and his store colleagues.

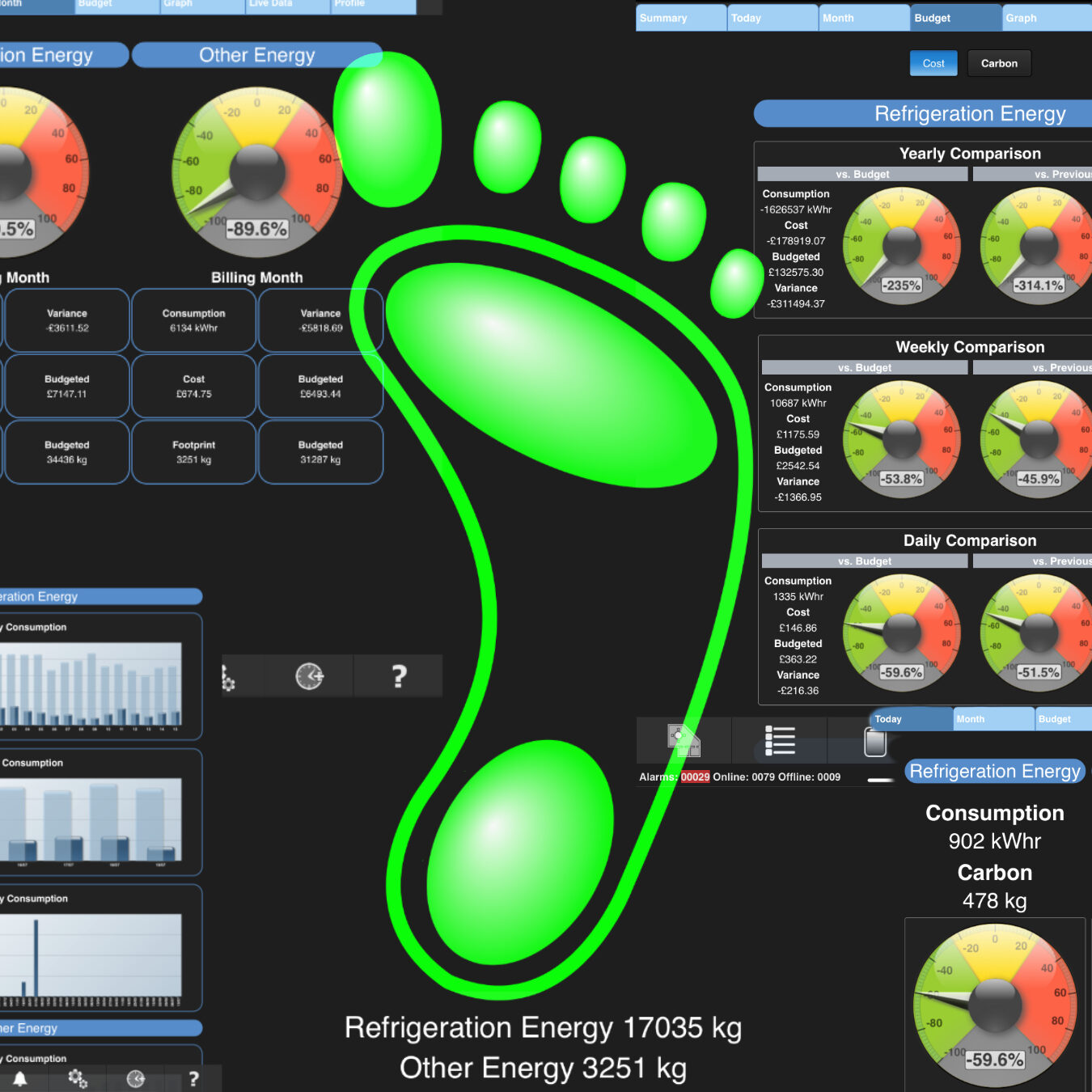

A review of the stores energy bills in 2020 and 2022 reveal a 25% reduction in the total amount of kWh’s used. Given that the store already uses over 60% less energy than a conventional refrigeration system. David is very impressed by this further significant reduction.