The rapid cooling of fresh and cooked food products to a frozen or chilled state is an essential process in the food chain, enabling food to be stored, distributed and consumed safely. Steve Shipp, Managing Director of Ultra Refrigeration, looks at the science behind this process and explores ways in which innovations can lead to operational benefits for food producers.

Blast freezing, blast chilling and tempering – overview

Blast freezing and blast chilling refers to the rapid cooling of food products down to a temperature where the food can be stored safely without its texture, flavour or integrity being impaired.

Chilling and freezing slows the growth of harmful pathogens and ripening enzymes within the food, so preserving for long periods perishable fresh foods such as seafood, meat, fruits and vegetables, and cooked products such as ready meals. This extends the shelf-life of foods, reduces food waste and enables the wide distribution of foods far away from their origin.

Freezing and chilling, if done properly, also maintains the flavour and structural integrity of the food so that it keeps its ‘fresh’ taste and textural quality right through to the final consumed product. The key here is to minimise the formation of ice crystals within the product during the cooling process, so that during the thawing process the cellular structure of the food is not damaged.

Tempering is the process of raising the temperature of frozen food to a point just below freezing to allow further processing such as cutting or slicing. Tempering requires very accurate temperature control, otherwise the quality of the food can be impaired.

Food manufacturers involved in any of these processes must balance operational requirements (such as processing speed, efficiency and energy use), with product quality (taste, texture, visual appeal), legal requirements (food safety and record keeping) and investment choices.

Regarding investment decisions, a food manufacturer must weigh-up the pros and cons of different types of solutions which can either be permanent installations or large scale “portable plug and play” units. Each has their merits and sometimes a mixture of both is required.

Blast freezing and blast chilling – requirements

Blast chilling is the rapid reduction of temperature of food items, usually from around 70°C for cooked foods, to 5°C or below, within 90 minutes. This rapid cooling is crucial for food safety, as it minimises the period where bacteria is most active (between around 8°C and 68°C).

Blast freezing reduces the core temperatures of food products down to -18°C. (Note: this industry-standard set point is currently under ‘discussion’ – a temperature of -15°C might not adversely affect food safety or quality and could lead to significant energy savings across the food chain, and help our move towards Net Zero.)

In the UK, the safety of frozen and chilled foods from production to retail consumption is covered by guidance from the Food Standards Agency, backed up by UK Government legislation. Businesses should have a Food Safety Management System (FSMS) in place, based on a Hazard Analysis and Critical Control Point (HACCP) study.

Common methods of blast freezing and blast chilling

For the organisation, the faster these lower temperatures can be achieved the better, because more product can be processed more quickly, resulting in production efficiency and energy cost savings.

However, this process must be achieved without impairing the product.

Outside of continuous, in-line process blast freezing and chilling, much of the food industry relies on pallet blast freezers. These large and often portable freezers are large enough to accept food packed on pallets to be loaded within them. The freezer is then set to blast freeze or chill the food, a process which is likely to take many hours, depending on factors such as; the kilowatt rating of the cooling plant; the ambient temperature; the temperature of the food entering the freezer; and the required finished food temperature.

The blast freezing/chilling cycle generally consists of cold air from an evaporator being channelled down a plenum chamber to the far end of the freezer, from where the air is drawn by fans back across, over and through the food to cool it and return the air to the evaporator for re-cooling.

The cooling effectiveness also depends on; how the food is packed on the pallets; the way the pallets are loaded into the freezer; the density and specific latent heat of the food itself; and the gaps allowed for airflow around, though and within the pallets.

Surface and product temperature probes may be used to determine when the required temperature has been achieved.

Blast freezing and blast chilling in practice

Effective, fast and efficient blast cooling does rely to a large extent on the skills of operators in determining the way food is packed on pallets, and the way pallets are packed within the freezer to optimise airflow over the product. Shrink-wrapped pallets should be avoided at all cost!

Blast freezers have historically had little in the way of controls or monitoring to ensure energy efficiency. They have traditionally been loaded up, the doors closed and the freezer left switched on over one night or over two nights until the product has reached temperature, when it would be unloaded.

However, these days, with more concern over energy costs and usage, operators are rightly demanding innovations to maximise energy efficiency.

Innovations in blast freezing and chilling

One of the problems with blast freezers is unevenness of cooling; that is, the product that’s first in line to the flow of cold air will tend to be cooled much quicker than the product that’s last in line. This means that by the time the last product reaches the target temperature of -18°C, the first product may be overcooled to -24°C or colder. That additional cooling is wasted energy.

Here at Ultra, we’ve found that by rearranging the airflow, ensuring that the coldest air is delivered to more product simultaneously, we can reduce pallet blast freezing times by around 50%.

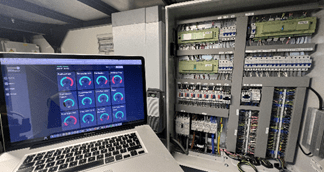

We’ve also incorporated detailed temperature monitoring, so once the products have achieved their required temperature, we can change the operation mode from blast freezer to cold store. Using speed driven compressors and fans allows demand and capacity to be dovetailed and reduce the overall energy consumption.

There is also the option to customise the control strategy, to regulate parameters such as temperature and time. Preset programs can also be provided; these can offer a range of cooling and ‘holding’ strategies, taking the guesswork out of rewriting software.

Our intuitive defrost strategy, and the use of reverse cycle defrost rather than heating elements, ensures defrost only occurs when required, minimising energy use.

Conclusion

Equipped with these kinds of innovations and controls, each Ultra Hybrid Air Blast Freezer can do three jobs – blast chilling, blast freezing and tempering. Having just one unit to do three jobs can be a lower cost, effective and flexible way forward for operators who need to be able to run different operations at different times.

And for agile rental operators it means they can service a wider range of applications from a smaller fleet, rather than have dedicated units for each function.

We can also build bespoke, specialist units to exactly meet your cooling requirements.

If you would like to discuss aspects of your existing refrigeration equipment, or want to talk about a new project, please get in touch by emailing us today at info@ultraref.co.uk or calling us on +44 (0) 330 2232404.