UK businesses are facing a challenging financial climate in 2025, with rising operational costs making it more difficult than ever to maintain profitability. The recent Budget announcements have introduced increases to employer National Insurance contributions, a higher National Living Wage, and continued high energy costs, all of which are putting pressure on businesses to find new ways to cut expenses.

With fuel and energy prices remaining high, companies are looking for smarter, more efficient ways to operate.

At Ultra, we understand the pressures businesses are under and are here to help reduce running costs and improve efficiency. By implementing intelligent automation and energy-saving technologies, businesses can cut refrigeration energy use by 20-40% and significantly reduce maintenance costs.

Whether you’re looking to offset rising wage costs, manage energy expenses, or improve sustainability, we have the solutions to help your business Thrive in ’25 and beyond.

Let’s explore how Ultra can future-proof your operations.

Introducing: The Ultra Energy-Saving Technology Series

This is the first in our series exploring the cutting-edge technologies Ultra Refrigeration can offer to help businesses cut costs and improve efficiency. Each month, we’ll take a closer look at a different smart refrigeration technology—from electronic expansion valves to heat recovery and intelligent control systems.

Individually, these innovations can provide significant savings. But when combined, they create a truly optimised refrigeration system that delivers long-term financial and environmental benefits.

Stay tuned as we uncover the best ways to future-proof your business and help you thrive in ’25!

Series 1: Electronic Expansion Valves (EEVs)

Smarter Refrigerant Control for Maximum Efficiency

✔ Lower Discharge Pressure = Reduced Compressor Power Usage

✔ Dynamic Superheat Control = Maximised Cooling Efficiency

✔ Adaptive Operation in Varying Load Conditions = Better Temperature Control

Industry Data Supporting These Savings

• A Danfoss study found that switching from a TXV to an EEV in supermarket refrigeration could reduce energy consumption by 10-20%, depending on the system design and operating conditions.

• ASHRAE research has shown that reducing discharge pressure and optimising superheat control can contribute to double-digit efficiency improvements in refrigeration systems.

• A case study by Emerson demonstrated 15-25% energy savings in commercial refrigeration systems after replacing TXVs with EEVs.

All of this adds up to improved temperature stability, reduced compressor wear, better monitoring and diagnostics, more system control and less energy use.

Can’t wait for next month’s instalment? Contact us now for a one-on-one meeting with our design engineers to find the optimal energy solutions for your refrigeration.

Spotlight Project

Can Ultra Upgrade This? Of Course We Can!

For businesses relying on chilling and freezing food, continuity of service is everything. However, as refrigeration plants age, they become less efficient, more unreliable, and increasingly expensive to maintain. One blast freezing company recently faced this challenge head-on—running an aging system with outdated mechanical controls, requiring daily on-site engineer checks, including at weekends, just to keep operations running smoothly.

With Ultra’s expertise, the company is now transforming its plant by upgrading to modern sensors and internet-enabled controls, bringing a new era of efficiency, automation, and reliability.

Affordability

Large refrigeration systems are expensive to replace, and while a full replacement would be ideal, the capital costs are simply not feasible within budget. Our system upgrade breathes new life into existing equipment and can be carried out without disruption to operations.

The Problem: High Costs, Low Efficiency, and Constant Monitoring

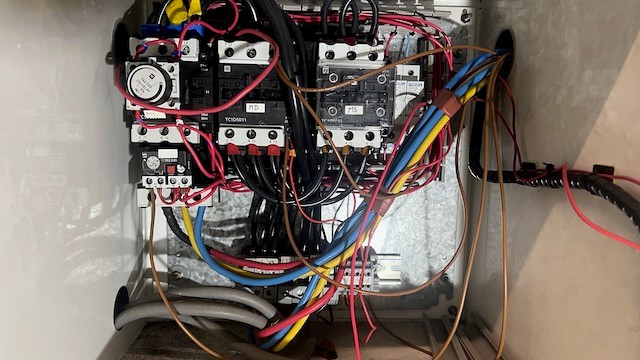

The existing refrigeration system relies upon:

❌ Old mechanical controls – prone to drift, requiring constant manual adjustment.

❌ Daily engineer visits – including weekends, wasting time and money.

❌ Frequent breakdowns – leading to costly emergency call-outs and production delays.

❌ Inefficient operation – causing higher energy bills and inconsistent freezing performance.

With engineers spending hours checking the plant every single day, and with no remote monitoring, any issue—big or small—required a physical site visit.

The Solution: Smart Controls & Remote Monitoring

Ultra’s upgrade project replaces the outdated mechanical control system with a modern, internet-enabled automation platform. This includes:

✔ Upgraded control panels – allowing for fully automated operation and precise system control.

✔ Modern sensors – providing real-time data on temperature, pressure, and energy usage.

✔ Internet-enabled remote monitoring – allowing engineers to check plant status and receive alerts from anywhere.

✔ Custom Control Software – matching the control software to the existing equipment enables modern control techniques whilst reducing installation time – no need for conversions and modifications to suit generic plant controllers.

✔ Automated diagnostics – reducing the need for manual fault-finding and troubleshooting.

The Benefits: Cost Savings, Efficiency & Reliability

The upgrade delivers both immediate and long-term savings, primarily through reduced labour and maintenance costs, in addition to lower energy consumption.

✅ No more daily engineer visits – Engineers can monitor plant status remotely, eliminating unnecessary site visits.

✅ Quicker fault diagnostics – Engineers will receive instant alerts, allowing them to identify and fix issues remotely before they become critical.

✅ Optimised plant efficiency – The system will adjust in real time, improving reliability and lowering running costs.

✅ Increased uptime and production security – With better reliability, the plant is less likely to fail during critical operations.

✅ Extended Lifespan – Delays the need for costly plant replacements and getting more value from their investment.

Is It Time to Upgrade Your Refrigeration System?

If your refrigeration plant is outdated, unreliable, or costing too much to maintain, Ultra can help. Contact us to discuss how smart automation and remote monitoring can transform your operations.

If you would like to discuss aspects of your existing refrigeration equipment, or want to talk about a new project, please get in touch by emailing us today at info@ultraref.co.uk or calling us on +44 (0) 330 2232404.